By John Wright

Discover the impact of GHG emissions by industry with our comprehensive analysis. Learn about the key sectors contributing to climate change.

Industry has a large part to play in the fight against climate change. By proactively working to reduce their greenhouse gas (GHG) emissions, businesses can garner public support, stay compliant with government regulations, and help build a better future for everyone.

Which sectors are producing the most greenhouse gasses? Why are they contributing so much to climate change? And how can they clean up their act?

How do GHG emissions impact climate change?

The key greenhouse gasses causing climate change are carbon dioxide, methane, nitrous oxide, and fluorinated gasses. Human-produced CO2 is the largest contributor to global warming. Methane is more powerful than carbon dioxide but has a shorter lifespan in the atmosphere. Nitrous oxide works similarly to CO2 but is rarer.

Greenhouse gasses aren’t the only substances impacting climate change. Other pollutants like soot have their own effects on the world’s temperature. Solar radiation and volcanic activity can also cause long-lasting global climate effects.

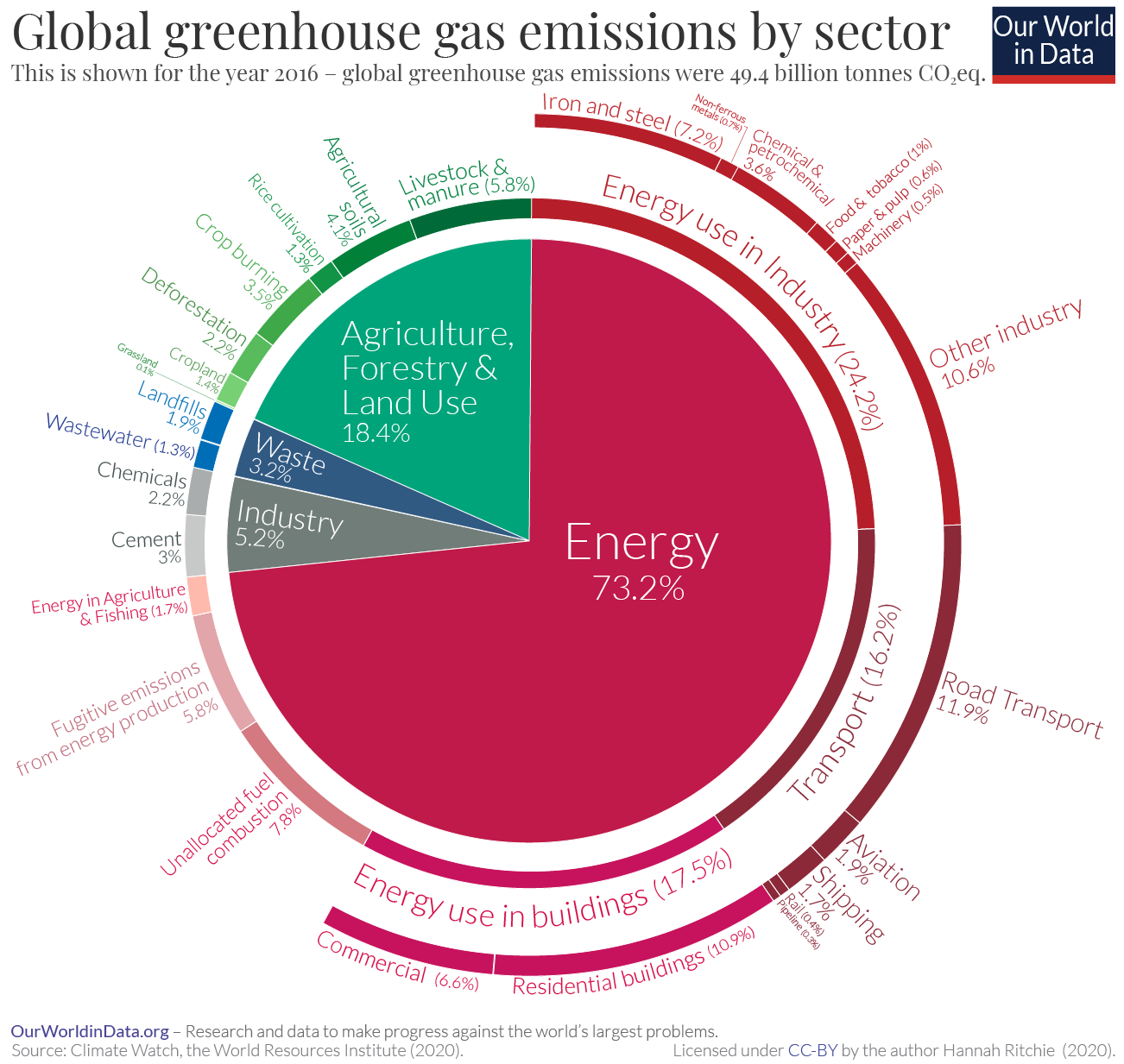

Global greenhouse gas emissions by sector

Source: Our World in Data

As you can see from the graph above, the vast majority (73.2%) of global greenhouse emissions are created in the energy sector. Agriculture, forestry, and land use are responsible for most of the remainder (18.4%), and industry and waste management account for most of the rest.

In this guide we’ll dive into each major source of GHG emissions. Let’s get started.

Energy

It makes sense that energy produces the majority of GHG emissions. Burning fuel to make heat alongside a polluting byproduct is at the core of many of the most common and cost-effective forms of energy generation like coal and natural gas.

Let’s take a closer look at how each sector creates emissions through their energy usage.

Energy use in Industry

Energy use in iron and steel production

Turning raw materials into iron and steel is an incredibly energy-intensive process, responsible for around 7.2% of global GHG emissions. It is also core to producing many of the products and services that humanity relies on.

Primary steel (fresh, unused steel) is made in a blast furnace. The producer starts with raw materials like iron ore, coal, limestone, and steel scrap. The iron ore is reduced to iron using coal and reducing agents like coke. Then, the iron is converted to steel in a blast furnace, and finally cast, rolled, and/or coated for final delivery. As you’d expect from something called a “blast furnace,” it’s extraordinarily energy intensive to heat up and use.

Reused or secondary steel is usually made using an electric arc furnace (EAF). An EAF uses electricity to melt steel scrap. Other sources of metallic iron can also be included, and alloying materials are introduced to adjust the steel to the desired final chemical composition.

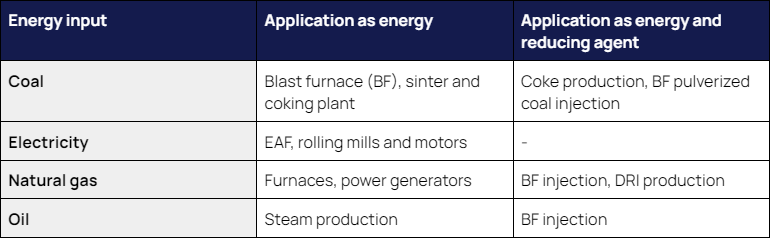

The table below shows how the steel industry relies on coal, electricity, natural gas, and oil to produce finished metal.

Source: World Steel Association

These inputs don’t just create greenhouse gasses, they also make up 20-40% of the total cost of steel production. Therefore, improvements in energy efficiency reduce production costs and improve competitiveness.

While vast amounts of heat and energy will always be required to produce steel, the source of that heat and energy can be transformed. Beyond that, creating primary steel is an inherently dirty job. Finding ways to recycle more steel, and creating a green electricity foundation to power the EAFs that create secondary steel is a clear priority.

The U.S. Department of Energy (DOE) has created a Low Emissions Steel Manufacturing Research Program to help foster decarbonization in the steel industry. Its pathways include:

- Alternative iron and steelmaking processes

- Hydrogen injection into the blast furnace and other existing processes

- Using clean energy sources

- Increased use of scrap metal

Energy use in chemical and petrochemical production

The chemical industry uses energy in two main ways: Fuel and feedstock.

Fuel is obvious. Converting chemical building blocks into useful chemical products takes vast quantities of energy. As high school chemistry students know, most chemicals in the world prefer to stay the way they are. It takes the application of heat or some other catalyst to force them to change.

Decarbonization of the fuel side of chemical production can be achieved through using less energy-intensive processes like advanced reactors, lower-carbon heating processes, and using lower emissions energy sources like hydropower and solar power.

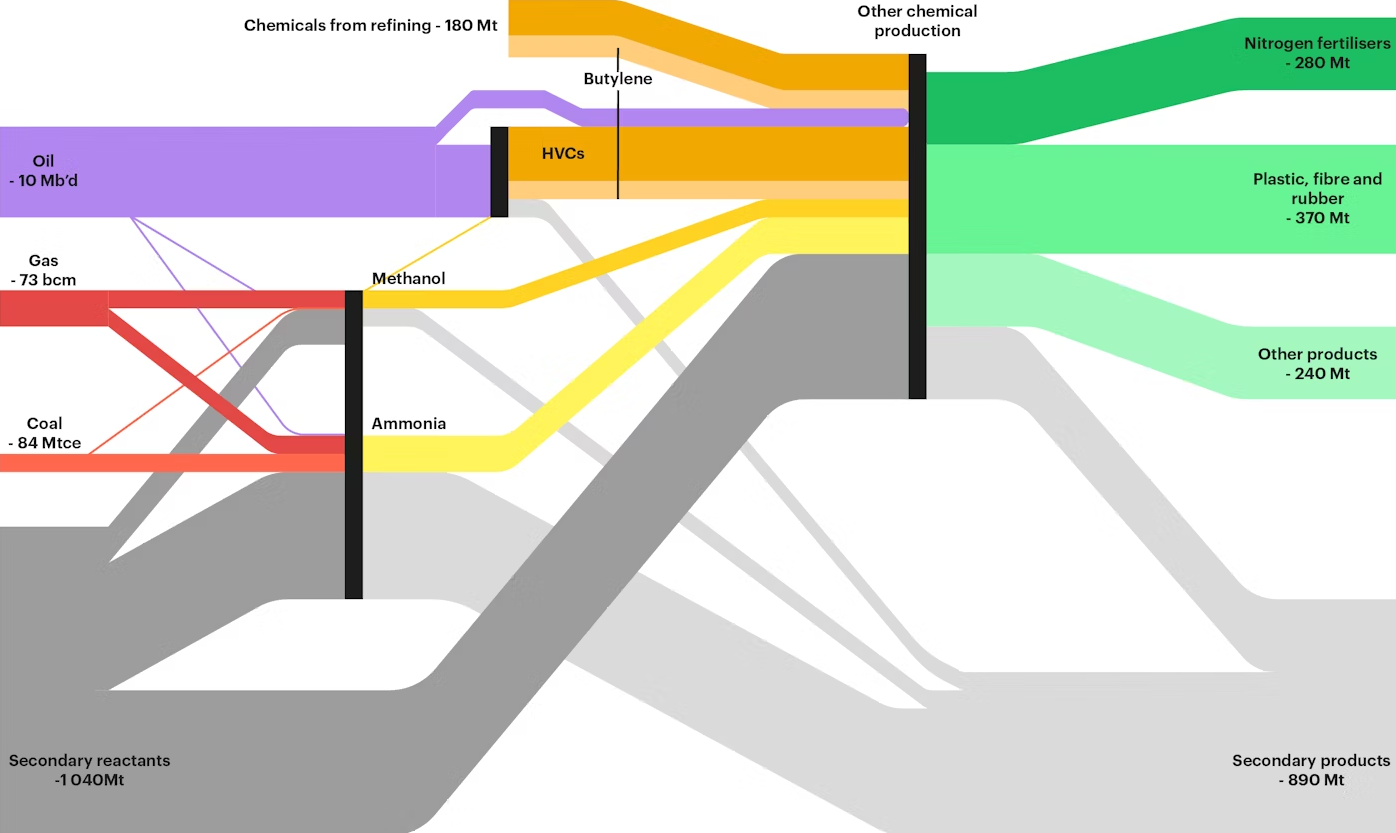

Feedstock are the inputs used to create finished chemical products. Oil, gas, and coal are all precursors to everyday chemicals, as the graph below shows. Because much of the feedstock is incorporated into the final product, the chemical sector is the largest industrial energy consumer, but produces fewer CO2 emissions than iron and steel.

Source: International Energy Agency

Chemical producers and research institutions are trying to reduce their dependence on GHG-emitting feedstocks through sustainable chemistry. Sustainable chemistry is the design, development, and use of chemicals and materials that:

- Have lower energy consumption and emissions

- Are less toxic to humans and the environment

- Have reduced impact on natural resources

- Have lower waste and are easier to recycle

Programs like the International Council of Chemical Association’s Responsible Care initiative are also helping the industry get cleaner and cut emissions.

Energy use in food, beverage, and tobacco production

Perhaps no sector is as diverse in terms of inputs, outputs, and processes as food, beverage, and tobacco. But from factory farms the size of a city to your local corner bakery, they all require energy and they all produce GHG emissions.

Energy inputs include the electricity required for packaging, refrigeration or freezing, the fuel for onsite grinding and milling plants, and the heat needed to dry, steam, or bake food.

Because of the vast array of processes and operations sizes, decarbonization can take many forms. The largest source of emissions comes from heating, so a major focus is in finding ways to reduce carbon intensity in that process. Companies are looking at innovating in areas like:

- Steam generation and water heating technologies

- Waste heat recovery and reuse

- Electrification of heating (including induction, resistance, and infrared)

- Waste-to-energy systems

- Electrofuels and ammonia

- Integration of captured carbon into dry ice, cooling, and refrigeration

Interested in learning about one great way to make food and beverage manufacturing more efficient? Check out our insight on Manufacturing Operations Management Software for Food & Beverage. As Harvard Business Review recently noted, digital transformation is key to achieving sustainability goals in F&B.

Energy use in buildings

Energy use in buildings is responsible for 17.5% of all GHG emissions. Buildings need to be constructed, heated, cooled, and lit, and all of those processes use energy.

This challenge becomes more acute by the day. Global floor area keeps increasing, and rapid growth in living standards in developing countries means more air conditioners, heaters, and other appliances. Homes, HVAC systems, and appliances last for years. That means decisions made today will have a powerful impact on future emissions.

Governments around the world are implementing minimum performance standards and broader and more stringent energy codes. More efficient and renewable building technologies are being developed like residential heat pumps, integrated solar energy systems, and advanced air conditioning technology. But more will be required to bring the industry in line with net zero goals.

You can see which buildings in most countries are sustainable for yourself by looking for a LEED plaque. LEED (Leadership in Energy and Environmental Design) is the most widely used green building rating system in the world. Buildings that achieve LEED status have environmental, social, and governmental goals baked into their design and construction.

Energy use in transport

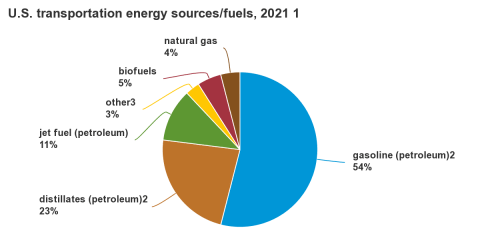

Transportation is a major component of world GHG emissions. And most of those emissions come from oil. Gasoline, jet fuel, and petroleum distillates account for almost 90% of the transportation energy in the United States, with similar statistics abroad.

- Gasoline is used in cars, motorcycles, light trucks, boats, and some types of aircraft.

- Distillate fuels are used by trucks, buses, trains, boats, and ships.

- Jet fuel is used by jet airplanes and helicopters.

- Biofuels are added to gasoline and diesel fuel.

- Natural gas is used in cars (usually in large government or private fleets), buses, trucks, and ships, as well as in the compressors that move natural gas through pipelines.

- Propane is used in fleet vehicles

- Electricity is used in EV vehicles and public mass transit systems

Source: U.S. Department of Energy

Stanford University has identified six key opportunities for decarbonizing and improving transportation:

- Design for less transportation with walkable and bikeable cities, remote learning and work, domestication and near-shoring of supply, and reduced consumption.

- Optimize the overall transport system by moving from carbon-intensive modes of transportation like individual cars, trucks, and planes to less carbon-intensive modes like public transport, rail, and biking.

- Promote behavioral change toward walking and biking when possible, using smart delivery instead of express delivery to reduce air demand.

- Electrify and transition to cleaner fuels like sustainable aviation fuel, green methanol for shipping, and hydrogen.

- Adjust gasoline, diesel, and jet fuel prices to reflect their social and environmental costs through methods like a carbon tax.

- Develop smart transport through the use of data analytics, AI, and IoT devices to optimize routing and reduce fuel consumption.

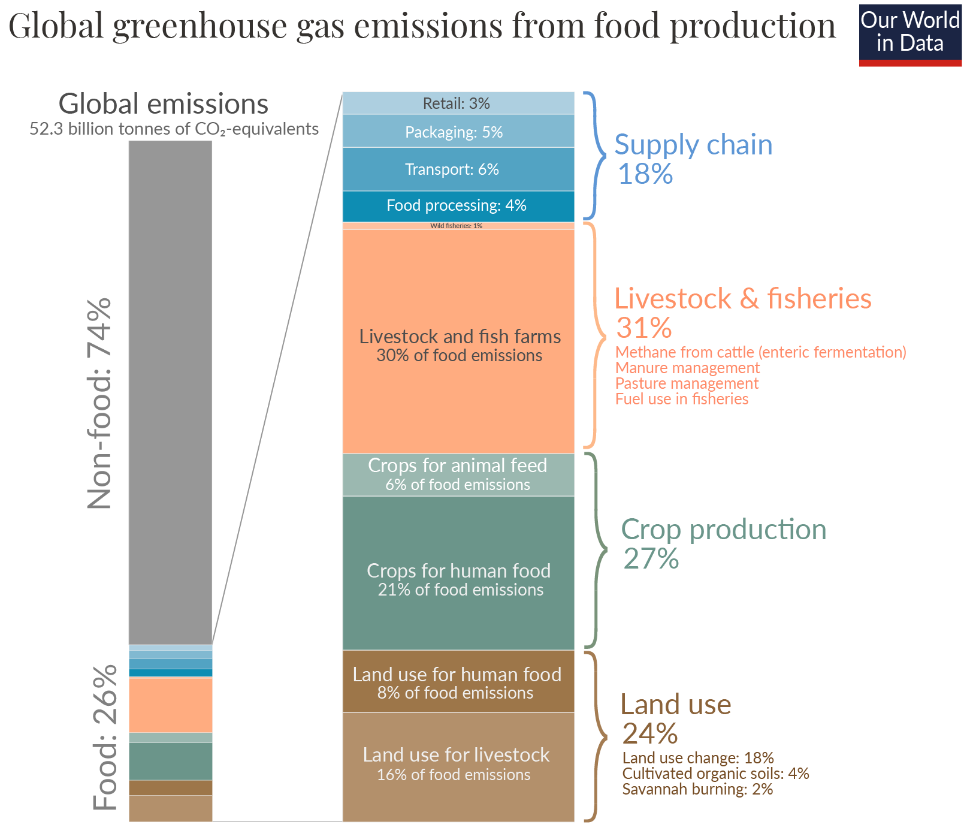

Agriculture, forestry, and land use

We need food to live. But food production creates greenhouse gas emissions that are warming the planet up to uninhabitable levels. Most GHG emissions from agriculture, forestry, and land use come from livestock and manure, agricultural soil production, and crop burning. By understanding and targeting each segment, we can substantially reduce global GHG emissions.

Across types of farming, associations like the American Farm Bureau Federation are working to create a more sustainable future for agriculture. The AFBF is currently working across climate smart farming, carbon markets, renewable energy, agricultural research, and building partnerships in sustainability.

Source: Our World in Data

Livestock and manure

While the image of farting cattle warming our atmosphere is ingrained in the popular imagination, it is far from the whole picture. Major sources of GHG emissions from livestock production include:

- Enteric fermentation: Cattle and sheep produce methane through their digestive process. Surprisingly, over 90% of it is emitted via burping. This is the largest source of livestock emissions.

- Manure: Solid waste produces methane and nitrous oxide. Liquid storage like “manure lagoons” emit the highest amount of GHG gasses.

- Feed production: Fertilizer and feed production emits CO2 and fertilizing crops generates nitrous oxide emissions.

- Land use change: Converting forest, grassland, and other natural environments into cropland and pastures releases the CO2 stored in biomass and soils.

- Processing: Emissions created from slaughtering, processing, and packaging livestock are usually included in global estimates.

Agricultural experts around the world at places like the University of California, Davis are working hard to reduce livestock GHG emissions.

Researchers and producers are developing and adopting technologies and practices like methane-reducing feed additives like red seaweed and breeding low-methane cattle that emit far less methane per pound of beef.

Adapting our land use helps keep CO2 locked away in biomass and soil. Livestock productivity improvements like improved cattle breeding, pasture management, crop-based feeds, and improved vet care are helping on the demand side of land use. On the supply side, governments are developing and enforcing stricter land use policies.

Finally, the only way to flatten the emissions curve over the long term is to lower the demand for meat per person. Moving from beef to poultry and fish, promoting largely vegetable based diets, and developing alternative proteins like plant-based meat are all ways to reduce the agricultural carbon footprint of each consumer.

Agricultural soils

Soils are both sources and sinks for GHG emissions.

When used for agriculture, management of agricultural soils can lead to more nitrogen being placed in the soil, leading to greater emissions of nitrous oxide. These management practices can include applying fertilizers (both synthetic and organic), growing nitrogen-fixing crops, and irrigation practices.

Other soil management practices like irrigation, tillage, and fallowing can increase and decrease the amount of CO2, carbon monoxide, and methane the land sinks or stores. However, these can be difficult to measure, so most carbon footprint models only estimate the emissions from fertilizer use.

GHG emissions from agricultural soils can be mitigated by carefully fertilizing crops with only the appropriate amount of nitrogen, and draining water from wetland rice soils during the growing season to reduce methane emissions.

Crop burning

Traditional agricultural practices often include burning crop residues like straw and stems in the fields they were planted in. This releases methane and nitrous oxide emissions into the atmosphere. Further advances in policy and practice in countries such as India and China, encouraged by international organizations like the UN Food & Agriculture Organization should help reduce its outsize impact on global emissions.

Industry

We’ve covered GHG emissions created by energy use in industry above. However, two industries, chemicals and cement, also create GHG emissions through the processes they use to make their finished products.

Chemicals

Decarbonizing the chemical industry poses a unique challenge, as unlike most other sectors, many of its emissions are not caused by the combustion of fossil fuels. Changing the feedstock used to create chemical products and the gasses used for chemical processes requires more creativity, including using recycled materials, captured carbon, and other reduction agents.

Greenhouse gasses are released when natural gas and petroleum feedstocks are converted into finished products. For example, olefins like ethylene, propylene, and butadiene are critical precursors for plastics, detergents and coatings. But creating them involves natural gas liquids like ethane. The entire process is energy and carbon intensive.

By capturing and converting sustainable feedstocks like waste gasses, biomass, renewable natural gas, and hydrogen, the chemical industry can make progress towards a net zero future.

Cement

Humanity makes more concrete than any other material on earth, and the growth of large developing nations like China and India means that amount keeps increasing.

Cement, the binder that holds the sand or crushed stone in concrete together, is incredibly energy-intensive to produce. Limestone must be baked in enormous kilns at very high heat, usually by fossil fuels, and CO2 is released as a by-product. Each kilogram of cement releases one kilogram of CO2.

Scientific American released a report last year looking at each step in the cement and concrete production chain, and condensing how each step could be made less carbon-intensive. From better precursor materials (basalt instead of limestone, oxygen-rich air to reduce emissions, adding mineralizers), to more electrification (electrifying steps in the process to allow for reliance on the power grid’s green power sources, EV transport instead of gas-powered), to better building codes and end-of-life planning, one of humanity’s dirtiest processes can get cleaner by the day.

Organizations like the Global Cement and Concrete Association are putting these recommendations in place through worldwide standards and certifications to help build a net-zero future.

How can my business reduce its GHG emissions?

If you work in one of these industries, you’re probably already looking at emissions from your own processes as well as those from your supply chain. It’s a complicated job, full of complex calculations, piles of paperwork, and plenty of scope for human error.

The Glassdome Product Carbon Footprint platform simplifies sustainability, with cutting-edge software and the guided expertise to help you master it.

Sound interesting? Just have a question about GHG emissions in your industry? Get in touch. It’s one small step for your company. But one giant leap for a cooler world.

More Articles