By Brent Morin

The world is slowly coming to terms with the impact carbon emissions have on climate. At the COP28 UN Climate Change Conference, the gathered nations agreed to “transition away from fossil fuels,” a major milestone for an event hosted by the United Arab Emirates. But acknowledging the problem is not enough.

Governments are taking actionable steps to reach the Paris Climate Agreement goal of “substantially [reducing] global greenhouse gas emissions to hold global temperature increase to well below 2°C above pre-industrial levels and [pursuing] efforts to limit it to 1.5°C above pre-industrial levels.” And that’s resulting in regulations like CBAM, California SB 253, and CSRD.

Most organizations are taking steps toward measuring greenhouse gas (GHG) emissions at the corporate level. But that isn’t granular enough to comply with these new, stricter targets. Organizations need to be able to measure impact at the product level and throughout their supply chain with a Life Cycle Assessment (LCA) or Product Carbon Footprint (PCF).

Your organization might already be embarking on an LCA or PCF. But before you begin, there are three challenges our PCF experts see every day that you should be aware of.

Data Availability

The challenges start at the beginning of the project. Just getting the data you need can feel overwhelming.

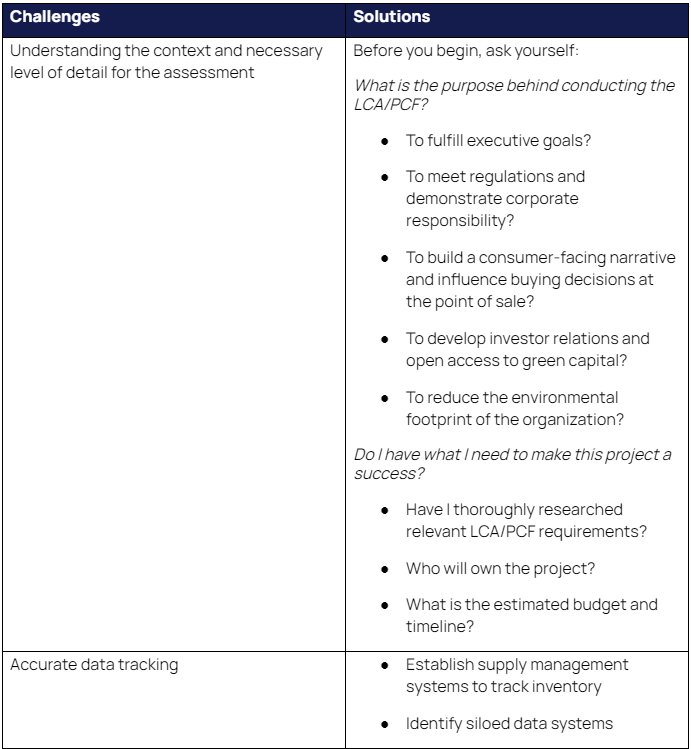

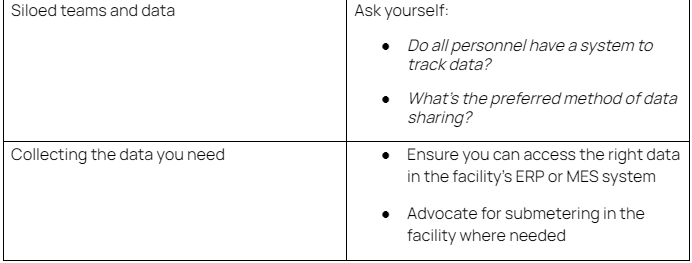

Data availability challenges can take a few forms, including understanding the context and necessary level of detail for the assessment, accurate data tracking, siloed teams and data, and collecting the data you need. The table below goes into further detail on possible solutions:

Data Quality

Not all data is good data. Your PCF data quality can be impacted by several factors, including:

- Scope: A well-defined and appropriately scoped LCA ensures accurate and relevant data. An inadequate scope may lead to incomplete or biased assessments.

- System boundaries: Defining clear and appropriate system boundaries is critical. Including or excluding certain processes can significantly impact results. Transparently documenting system boundaries helps ensure a reliable assessment.

- Data collection methods: Relying on incomplete sources or biased sampling compromises the reliability and representativeness of the data and influences the overall quality of the LCA results. Direct measurements and comprehensive surveys lead to higher accuracy and completeness.

- Data quality indicators: Indicators like reliability, representativeness, and precision help analysts assess and report the quality of the data used in the LCA or PCF.

- Data sources: High quality data comes from reliable and accurate sources. Using data from reputable and well-established sources (we often use ecoinvent) improves overall assessment quality.

- Data completeness: Incomplete data can lead to uncertain and inaccurate results. Make sure you cover all relevant stages of the life cycle, from raw material extraction to disposal.

- Data relevance: Make sure assessed data is relevant to the specific product or process being assessed. Using irrelevant or outdated data can compromise accuracy.

- Data uncertainty: Uncertainty comes with the LCA / PCF territory, and it's important to communicate the uncertainties associated with the data. Common techniques used in this process are sensitivity analysis and uncertainty analysis.

- Allocation methods: Allocation refers to how you distribute environmental burdens among different co-products or processes. The choice of allocation method will affect your results, and the method used should be justified and transparent.

- Temporal considerations: Changes over time, like technological advancements or shifts in energy sources, can affect environmental impact. Considering temporal aspects of data makes for a more accurate assessment.

- Geographical variability: Environmental conditions can vary geographically. Accounting for regional differences in data, especially for processes with location-specific impacts, enhances accuracy.

- Assessment methodologies: Your choice of impact assessment methodology (e.g., TRACI, ReCiPe, CML, Eco-Indicator) can influence the results. Different methodologies may yield vastly different environmental impact indicators.

Relying on Assumptions

It’s easy to lean on assumptions without even realizing you’re doing it. Unfortunately, assumptions can lead to incorrect impact assessments.

LCAs or PCFs can be based on assumptions for the following reasons:

Insufficient data is available: A minimum of one year of data is needed to conduct a LCA study.

Critical data hasn’t been tracked: Examples of data that is often not tracked include:

- Waste generated at a manufacturing facility and their method of disposal

- Water/wastewater treatment chemicals used at the manufacturing facility

- Support materials like grease

- Transportation distances for raw material and distribution

- Production allocation

Database categories don’t match your manufacturing process: Secondary databases contain commonly used materials and processes. When a manufacturing plant uses a complex chemical, it might not be present in the database. Which material or process in the database you choose to match to that complex chemical can impact your results.

Materials and processes in datasets are not present for the region of interest: For example, ethylene oxide production processes in North America, the World, and European Union may be present in the databases, but not for production of ethylene oxide in South Korea. This means the electrical grid mix to produce the ethylene oxide will not be representative of the grid mix in South Korea, leading to incomplete data.

How Can I Make These Pain Points Less Painful?

As you can probably tell by now, you’re going to need to spend a lot of time reviewing your data for completeness, quality, and relevance. And you’re going to need to make sure you’re using the right processes and methodologies to work with it.

You know what makes that easier? Working with experts.

With Glassdome, you’ll have consultants guiding you through data collection and helping you establish your data pipeline. And once the platform is set up, you’ll get monthly reporting to help you stay compliant and adjust as needed. It’s sustainability, simplified.

Get in touch with one of our PCF experts to learn more.

More Articles